Liquid Fantasy

TeckWrap sublimation paper (100 sheets)

TeckWrap sublimation paper (100 sheets)

Couldn't load pickup availability

Sublimation paper is a special kind of coated sheet that helps transfer vibrant and beautiful prints onto polyester garments or fabrics with high polyester content. You will need a special dye sublimation ink for this process and a printer that can print with it. The sheet holds the ink till the time the design is printed on a compatible surface.

Features:

- Size: A4 x 100 sheets. This is the perfect size to make small to medium-sized designs.

- Printer compatibility: Compatible with inkjet printers loaded with sublimation Ink. It will give excellent performance with both the special dye-sublimation printer and a converted inkjet printer.

- Print white side: Print on the white side. This is the one with the coating that will hold the ink.

- High quality ink absorption: The coating is high-grade that absorbs and holds the sublimation ink without smudging, bleeding, or fading during the transfer process.

- Handles complex designs: A sturdy and reliable sheet that can handle intricate designs and detailed graphics. You can unleash your creativity and print any design that you like.

- Ensures even ink flow: Ensures even ink distribution and reduces the risk of defects in the transferred image. Ensures even ink distribution and reduces the risk of defects in the transferred image.

- No curling: The paper will not curl or wrinkle and promises an excellent overall color vibrancy and sharpness of the final print.

- Quick drying: The sheet dries quickly preventing the smearing of the ink. This also reduces the transfer time.

- Fabric compatibility: To be used with white or light-colored polyester. It can also be used with fabrics that have ≤30% cotton content and coated objects.

- High transfer rate: Transfer rate ≥98%. The paper has very high color transfer efficiency.

-

Eco-friendly: Made with eco-friendly materials and processes, appealing to environmentally conscious consumers.

Things you should know:

- Sublimation temperature chart.

- How to sublimate on dark shirts.

- Best sublimation paper for dark shirts/

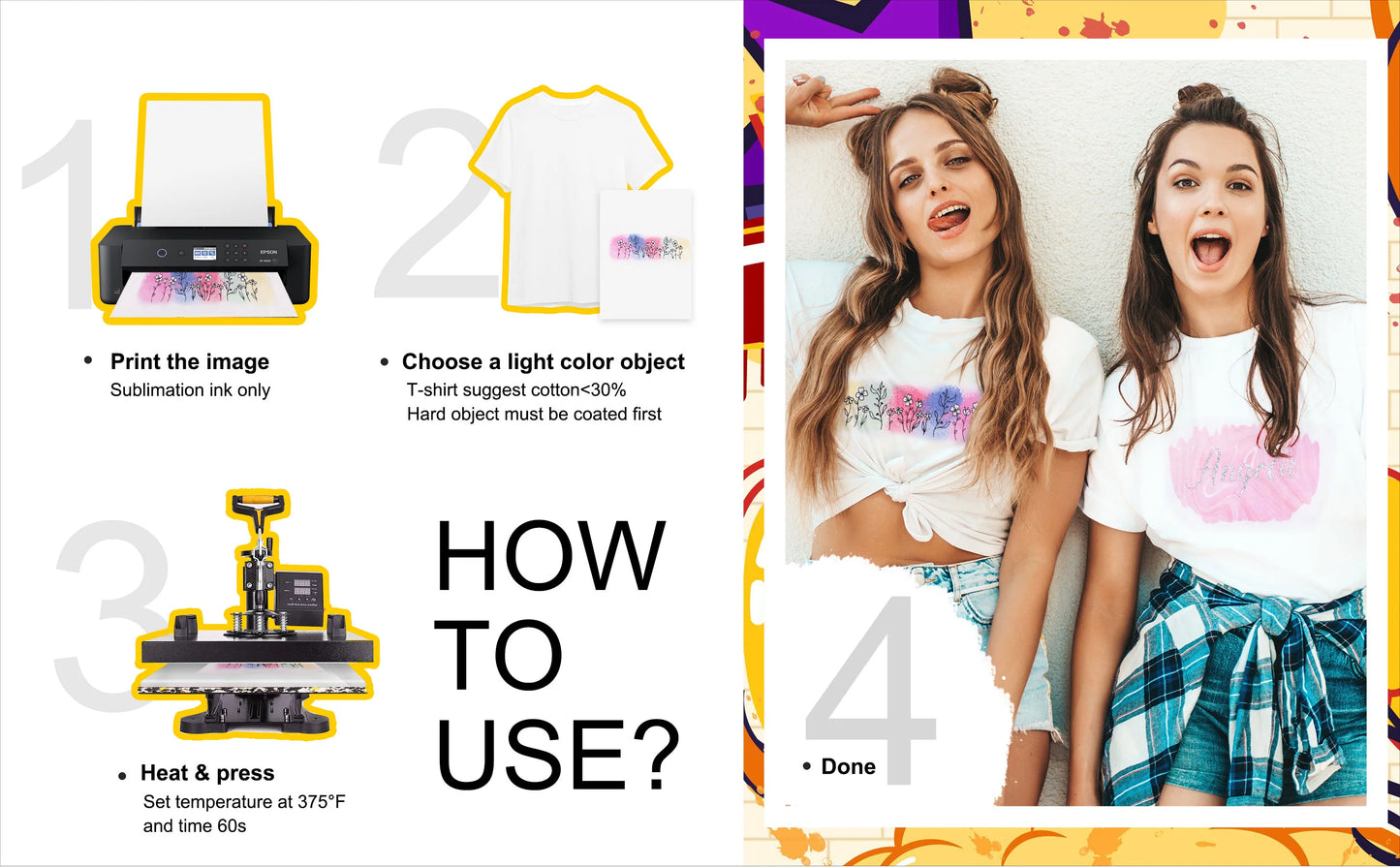

How to print using sublimation paper?

You can easily print any merchandise made of compatible materials using sublimation paper. Here’s how:

- Finalise design: Use graphic design software to finalize the design. Do not forget to flip it horizontally.

- Print design: Print the design onto the sublimation paper using a compatible inkjet printer that holds the dye sublimation ink. Keep it aside for drying.

- Clean surface: Clean the surface by removing any dust or debris and ensuring that it is free of moisture. If it's a fabric, press it to remove creases.

- Transfer design: Place the sublimation paper with the printed design onto the substrate and apply heat and pressure. The sublimation ink turns into gas, and the gas is then absorbed by the fabric, resulting in a permanent transfer of the image.

- Cool down: Carefully remove the sublimation paper and allow the transfer to cool completely. Sublimation works best with polyester or with fabrics that have at least 85% of it.

The ink needed for sublimation paper:

You need a special kind of ink to work with sublimation paper called disperse dyes or dye-sub ink. This has the quality to transform from a solid state to a gaseous state without turning into a liquid when high temperature is applied to it. It is then absorbed by the polyester fabric and turns into a solid state again upon cooling down forming a permanent bond with the fabric, or other suitable surface.

Sublimation heat press settings: time, temperature and pressure:

| Product | Temperature settings (in °C) | Sublimation time | Pressure | Tips |

|---|---|---|---|---|

| Polyester fabric | 200 to 205 °C | 35 to 40 seconds | Medium pressure | Pre-press the shirt for 5 to 10 seconds before the actual printing of the sublimation design to eliminate moisture. |

| Ceramic sublimation mugs | 190 to 200 °C | 20 seconds | Medium to firm pressure | After pressing, do not remove the mug on the mug press machine. Let it cool and stay for one minute. |

| Ceramic sublimation plate | 190 to 200 °C | 60 seconds | Medium pressure | Make sure to remove plastic coating before pressing the design. |

| Sublimation tumbler (made of metal) | 160 to 170 °C | 25 seconds | Medium to firm pressure | Always use a thermal tape especially when printing on curved surfaces of the tumbler. |

| Sublimation umbrella | 190 to 195 °C | 45 seconds | Medium pressure | Make sure that the rib and rib tip of the umbrella does not come in contact with the heat as it is made of plastic and may melt. |

| Neoprene fabric (mouse pads, coasters, vapor foam kit) | 200 to 205 °C | 40 seconds | Medium pressure | Make sure to totally clean the heat press machine before printing. Any dirt or dust may leave unwanted print marks on the neoprene fabric. |

| Sublimation metals (Mobile phone covers, keyring, metal plates, trophy covers) | 190 to 200 °C | 60 seconds | Medium pressure | Place an absorbent sheet on the bottom of the heat press machine. |

| Sublimation face mask | 240 to 245 °C | 45 seconds | Medium pressure | Remove the inner cotton layer (if present) on the mask before pressing it. |

| Sublimation over heat transfer vinyl | 175 to 180 °C | 30 to 35 seconds | Medium pressure | Press the vinyl first on the fabric and let it cool before sublimating. |

| Canvas material | 185 to 190 °C | 40 seconds | Medium pressure | Pre-press the canvas material before sublimating the fabric. |

| Polyester cushion covers | 200-205 °C | 35 to 40 seconds | Medium pressure | When printing on polyester cushion covers, pre-press the fabric for 5 to 10 seconds just like pressing a shirt. |

Video link:

How to sublimate a jelly cup tutorial (youtube.com).

Note: this is not HTV, vinyl or inkjet printable vinyl.